Application Video

Screw Driving

Polishing

Glue Dispensing

Pick and Place

Packaging

Painting

Welding

Palletizing

Flexible Assembly

Procedure Transferring

Quality Inspection

More

Remote Programming

No longer limited to geographical boundaries and also realize one mobile terminal controls multiple robots.

Learns and Remembers

Manually drag the end of the robot to the appropriate point, it learns and remembers autonomously to complete programming.

Can be operated

by anyone

Even users with zero basic knowledge can easily teach.

High production

efficiency

Reduce the lazbor intensity of workers CT(Cycle Time)

is faster and productivity is higher

Wireless Linking

No annoying wires attached! Enjoy clean and safe space with JAKA cobots.

Remote Monitoring

Monitor cobot’s tasks and set alerts with unique security authentication system

No Teach Pendant

JAKA APP is available on tablets, smartphones and PCs. Teach your cobot easily.

Drag Teaching

Thanks to easy drag teaching and 6 joints providing high maneuverability, simply move the cobot to any position, and it will memorize it instantly.

Graphic Programming

With JAKA Cobots’s unique security authentication mechanism, we can implement remote task delivery.

JAKA Product List

JAKA MiniCobo

Product Features:

- JAKA MiniCobo Cobot has the characteristics of lightness, compactness, high flexibility, and easy installation.

- It uses an integrated intelligent drive module to achieve a lightweight design while having superior performance; in addition, rich secondary development interfaces provide customers with more choices in different scenarios.

- JAKA MiniCobo Cobot has a small appearance, simple and intuitive operation, low noise, and high cost performance. It is especially suitable for consumption, service, education and other fields.

Product Parameters

| Payload | 1 kg |

| Weight(W cable) | 9.4 kg |

| Working Radius | 580 mm |

| Repeatability | ±0.1 mm |

| Axis | 6 |

| Programming | Graphical I Drag and drop |

| Teach Pendant | PC, mobile, tablet |

| Collaborative operation | In compliance with GB 11291.1-2011 |

| Certifications | RoHs、CE、13849、KCs |

JAKA Zu 3 Cobot

About JAKA Zu 3

- The JAKA Zu 3 offers cutting-edge human-robot collaboration. With drag-and-drop graphic programming, teaching and operating the cobot becomes effortless. The built-in torque feedback ensures safety, regardless of the utilization of its 3 kg payload, within its working radius of 626 mm.

- It is ideal for tasks such as screwdriving, electronic assembly, small surface pick-and-place operations and other line and maintenance tasks. Its versatile mounting options enable it to be positioned anywhere - fixed at an angle, upside down, or even vertically.

- Its compact size, coupled with full functionality, makes it well-suited for 3C electronics and advanced manufacturing.

Product Parameters

| Payload | 3 kg |

| Weight(W cable) | 12 kg |

| Working Radius | 626 mm |

| Repeatability | ±0.02 mm |

| Axis | 6 |

| Programming | graphical, visual |

| Teach Pendant | MT (PAD/Mobile) APP |

| Collaborative operation | in compliance with GB 11291.1-2011 |

| Certifications | CR, CE, ISO/TS 15066 |

JAKA Zu 5 Cobot

About JAKA Zu 5

- With a 5kg payload and a working radius of 954mm, the JAKA Zu 5 cobot is perfectly suited for repetitive operations such as picking and placing, welding, assembly, and more.

- Its features are specifically optimized for use in 3C electronics, automotive, and other industries that demand high levels of precision.

- The visual and collision protection systems of the JAKA Zu 5 ensure its ability to function in harsh and unpredictable environments, eliminating the need for a safety fence.

- Its compact size and flexible mounting options facilitate easy placement at any angle – vertically, horizontally, on a slope, or even upside down on the ceiling.

Product Parameters

| Payload | 5 kg |

| Weight(W cable) | 23 kg |

| Working Radius | 954 mm |

| Repeatability | ±0.02 mm |

| Axis | 6 |

| Programming | graphical, visual |

| Teach Pendant | MT (PAD/Mobile) APP |

| Collaborative operation | in compliance with GB 11291.1-2011 |

| Certifications | CR, CE, ISO/TS 15066 |

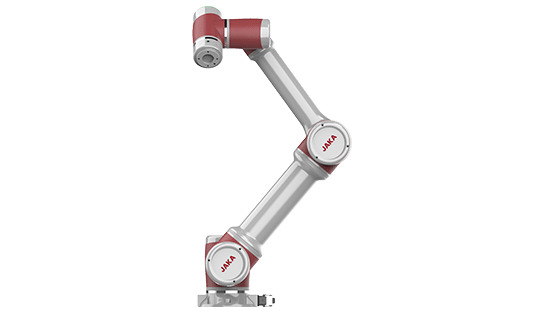

JAKA Zu 7 Cobot

About JAKA Zu 7

- Working for extended hours with weights of up to 7 kg can be exhausting for anyone. However, the JAKA Zu 7, with a payload of 7 kg, can manage this for 50,000 continuous hours within a working radius of 819 mm!

- Repetitive tasks like welding, packaging, palletizing, picking and placing and more pose no problem, freeing employees to undertake less physically demanding tasks required in a smart factory. It can be mounted at any angle - horizontally, vertically, on a slope or hanging from above.

- While most of our JAKA Zu 7 customers are from the automotive, 3C electronics, advanced manufacturing, renewable energy, medical devices, chemical and synthetic fibers industries, this cobot is suitable for many other industries too.

Product Parameters

| Payload | 7 kg |

| Weight(W cable) | 22 kg |

| Working Radius | 819 mm |

| Repeatability | ±0.02 mm |

| Axis | 6 |

| Programming | graphical, visual |

| Teach Pendant | MT (PAD/Mobile) APP |

| Collaborative operation | in compliance with GB 11291.1-2011 |

| Certifications | CR, CE, ISO/TS 15066 |

JAKA Zu 12 Cobot

About JAKA Zu 12

- The JAKA Zu 12 offers a payload of 12 kg and a larger working radius of 1327 mm compared to previous models in the JAKA Zu series. Capable of completing tasks that would typically require at least two people, it can operate continuously for 50,000 hours.

- Featuring a 6-axis configuration, the JAKA Zu 12 offers reliability and precision. Boasting an exceptional repeatability of ±0.03 mm.

- Despite its high payload capacity, it remains relatively lightweight and can be mounted at various angles - vertical, horizontal and everything in between.

- Its combined flexibility, safety features and reliability make it an ideal fit for applications in the automotive and auto parts industry, advanced manufacturing, household appliances, food packaging, and much more.

Product Parameters

| Payload | 12 kg |

| Weight(W cable) | 41 kg |

| Working Radius | 1327 mm |

| Repeatability | ±0.03 mm |

| Axis | 6 |

| Programming | Graphical I Visual |

| Teach Pendant | MT(PAD/Mobile)APP |

| Collaborative operation | In compliance with GB 11291.1-2011 |

| Certifications | CR, CE, 15066 |

JAKA Zu 18 Cobot

About JAKA Zu 18

- The JAKA Zu 18 has the largest payload of 18 kg within the JAKA Zu range. Additionally, it has a significant working radius of 1073 mm.

- Its capabilities range from standard heavy-lifting tasks to delicate and precise operations, leveraging its 6-axis configuration to achieve an outstanding repeatability of ±0.03 mm.

- Despite its large payload, the Zu 18 is incredibly safe. Equipped with visual and torque-feedback collision protection systems, it operates seamlessly in any environment without the need for a safety fence.

- JAKA Zu 18 is perfect for use in diverse tasks such as packaging, palletizing, welding, testing, screw tightening, mold injection, bonding and more.

- Its utility spans across various industries, including the production or testing of medical devices, metal processing, chemical manufacturing, standard manufacturing and warehousing.

Product Parameters

| Payload | 18 kg |

| Weight(W cable) | 35 kg |

| Working Radius | 1073 mm |

| Repeatability | ±0.03 mm |

| Axis | 6 |

| Programming | Graphical I Visual |

| Teach Pendant | MT(PAD/Mobile)APP |

| Collaborative operation | In compliance with GB 11291.1-2011 |

| Certifications | CR, CE, 15066 |

JAKA Zu 20 Cobot

About JAKA Zu 20

- JAKA Zu 20 is our new collaborative robot, designed for tasks that require heavier payload and extended reach.

- This cutting-edge robot builds upon the renowned qualities of the JAKA Zu series, offering simplicity, safety, reliability, and precision. With an impressive reach of 1780 mm and a payload capacity of 20 kg it excels in heavy-duty and large- capacity applications. The IP65 protection adds an extra layer of reliability and resilience, ensuring the Zu 20 is also suitable for industrial environments where dust, dirt and water are present.

- From machine tending to material handling, welding to dispensing, palletizing to packaging, the JAKA Zu 20 is your ultimate partner for diverse industrial needs.

Product Parameters

| Payload | 20 kg / 44.1 lbs |

| Weight(W cable) | 41 kg |

| Working Radius | 1780 mm / 70.1 in |

| Repeatability | ±0.05 mm |

| Axis | 6 |

| Programming | Graphical I Visual |

| Teach Pendant | MT(PAD/Mobile)APP |

| Certifications | CE、IOS13849、KCs、NRTL |

JAKA Zu S Series

JAKA ZU S cobot family

Compact and lightweight, the JAKA ZU S series embodies numerous innovations emphasizing safety and precision. Each unit is equipped with an industrial force sensor, which can be positioned either at the base or the end of the cobot arm. Complemented by a force control algorithm, this sensor offers several advantages

Primarily, it enables three distinct control modes: constant force, normal tracking, and speed mode. Additionally, it grants the cobot the ability to 'sense' its

surroundings and objects it interacts with.

By continuously monitoring external forces, it ensures that predetermined safety thresholds are never exceeded, safeguarding both humans and the items being handled. Moreover, dynamically interfaces with the JAKA app, providing real-time display of force values and control settings.

Altogether, this makes the JAKA ZU S cobots perfectly suited for polishing, sanding or grinding complex surfaces, as well as PCB assembly, palletizing and more.

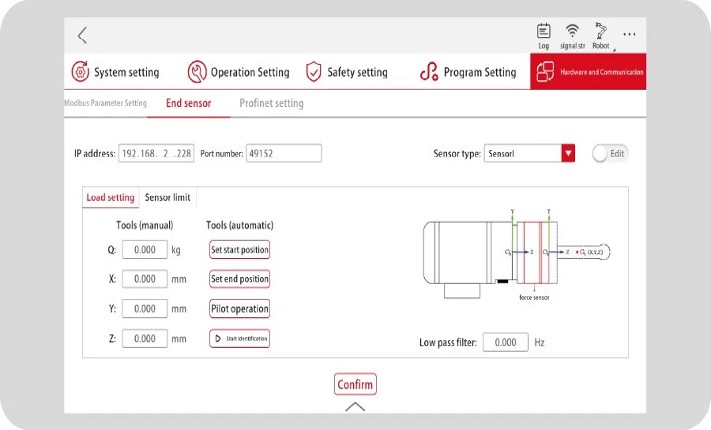

JAKA Zu s features

Force Sensor

The industrial force sensor, which can be installed at the base or the end of any Zu S series cobot, increases precision. It gives the cobot the ability to accurately perform tasks like palletizing, polishing, or sanding on complex surfaces.

Force Control Module

The force control module, which users can interact with using the JAKA app, shows force values, and creates a full-arm collision detection capability. If any external force exceeds the designated security value, the cobot ceases to apply more force immediately. There are three control modes available: constant force, normal tracking and speed mode.

Key features of JAKA All-in-one cobots

Integrated Vision System

The JAKA All-in-one cobots represent a leap forward in human-robot collaborative work. Along with wireless teach and graphic programming comes visual feedback: a camera-utilizing system that ensures precision and safety, while considerably broadening the range of tasks cobots may be assigned to.

Fixed or mounted at the end of the cobot, the JAKA Lens 2D features a high-quality lens, together with a specialized light source module providing users with full functionality and a 2D vision experience.

MiniCab

Thanks to Minicab controller every JAKA All-in-one cobot feels at home mounted on an AGV.

Cobots and AGVs (known as automated guided vehicle) on their own are remarkably useful; without the need for human intervention, AGV-cobot pairings can complete warehousing, and inspection tasks independently.

Size of the Minicab is: 180x128x47 mm I Weight: approx. 1.1 kg

JAKA Pro

Harsh Industrial Environment? Switch to Cobots

• The JAKA Pro cobots have IP68, meaning that they are immune to dust, small particulates and liquids such as water and oil.

• They are capable of working non-stop for years in environments that would be intolerable for humans, full of metal and wood shavings, dust, wind or rain, in temperatures ranging from -10 up to 50°C (14 to 122°F).

• The series includes cobots that can handle payloads of 5 up to 16kg, with working radii of up to 1713mm.

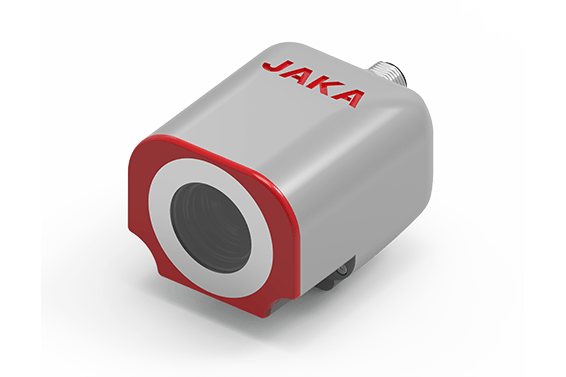

JAKA Lens 2D

- JAKA Lens 2D integrated camera adopts 2D high-resolution industrial camera and is equipped with a special light source module and optional camera lens to provide users with comprehensive functions and experience of 2D vision.

- After the professional industrial design, it is small and lightweight and has a delicate appearance. It can realize 2D vision function by the external fixed installation or by installing it at the end of the robot

JAKA Lens 2D Parameters

| Lens | Lens 2D CGC500-F08 | Lens 2D CGC500-F16 |

| Resolution | 2592×1944 | 2592×1944 |

| Max frame rate | 24fps | 24fps |

| Data interface | Gige | Gige |

| Color mode | Black and white / color | Black and white / color |

| Lens focal length | 8mm | 16mm |

| Object distance | >100mm | >100mm |

| Vision | >70×50mm | >35×25mm |

| Precision | >0.08mm | >0.04mm |

| Image processing | Soft-trigger image acquisition, single frame processing time within 1s | Soft-trigger image acquisition, single frame processing time within 1s |

About JAKA

JAKA Robotics was founded in 2014. stands for “Just Always Keep Amazing”.

It is a high-tech company aiming at innovation and R&D for new generation of cobots and smart factory.