Quick Response Heater and Control System

Asano Quick Response Heater is developed in order to heat thermal sheet in the Thermoforming Machines. (Patent granted)

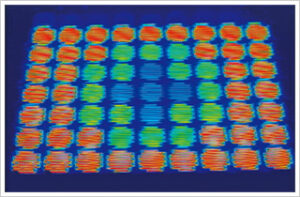

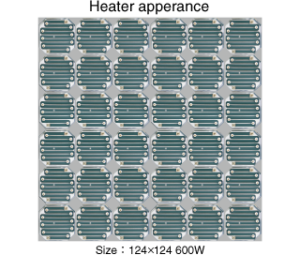

Quick Response

Compared with conventional ceramic heaters, Asano Quick Response Heater is approx. 60 times quicker in responsiveness. The heater can be switched off when not in use, so that save electric energy. Compared with the thermoforming machine with rod heater or ceramic heater, Asano machine-FCS and FCSP with Asano QRH save the electric energy by 50%.

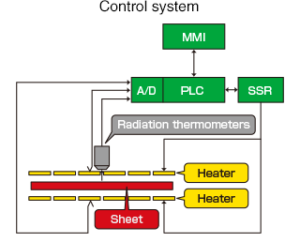

Sheet Temperature Control

The sheet temperature is controlled steadily through feedback from actual sheet temperature by thermometers. Sheet temperature control is functioning to prevent sheet’s surface’s overheating and heats inside of sheet.

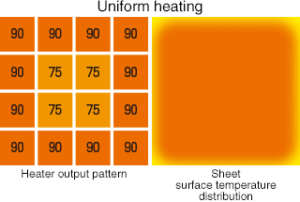

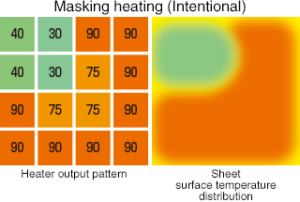

Optimum Temperature Distribution for heat Shielding|

( Separate Phase Control for each Heater Elements)

Change the pattern of each heater’s output ratio in order to heat the sheet effectively.

Exceptional Proposals for Thermoforming

-

Annealing oven for foamed sheet forming

-

Annealing equipment for optical sheet forming

-

Drying oven for painting etc

Details about Products

FLB

High-mix low Volume Production continuous thermoforming machine

Main Product: Blister pack,Industrial tray, food container

Main Product: Blister pack,Industrial tray, food container

| Model |

Max. Forming area(W × L, mm) |

Max. Forming Depth( mm ) |

Forming Method |

| FLB-21 | 600 × 1000 | Height of formed part positive 100 negative 100 | 20 |

| FLB-31 | 800 × 1000 | Height of formed part positive 100, negative100 | 20 |

Related Video

FLC

High-performance pressure and vacuum Thermoforming Machine

-

Pressure and Vavuum Thermoforming Machine for Mass production.

-

This best-selling machine has been sold over 350 units.

Suits for lunch box, Rice container -

Natto container, noodle container, industrial tray, blister pack etc.

| Model |

Max. Forming area(W × L, mm) |

Max. Forming Depth( mm ) |

Max. mold clamping force (kN) |

| FLC-315PC5 | 800 × 800 | 150 | 450 |

| FLC-415PC5 | 1000 × 1100 | 150 | 450 |

Related Video

FJ

High-performance pressure and vacuum Thermoforming Machine

| Model | FJ-1.2-EX |

| Forming Area | Max. 750 (W) × 580 (L) |

| Forming depth | Max upper lower draw positive 120mm |

FLD

Pressure and vacuum thermoforming machine with steel rule die cutting

MainProducts: Blister pack, Industrial tray

| Model |

Max. Forming area(W × L, mm) |

Max. Forming Depth( mm ) |

Forming Method |

| FLD-208VC4 | 600 × 600 | Height of formed part positive 80 negative 80 | Vacuum and pressure forming |

| FLD-208PC4 | 600 × 600 | Height of formed part positive 80 negative 80 | Vacuum forming |

Related Video

PLS/PLS7

Continuous Trimming Machine

Die-punching blade type’s trimming machine. Connected with FLC, CLS etc forming machine, production line gets high speed and stable.

| Model |

Max. Forming area(W × L, mm) |

Max. Forming Depth( mm ) |

Max. trimming speed (spm) |

| PLS7-315B4 | 800 × 320 | 150 | 100 |

| PLS-410B4 | 1050 × 320 | 100 | 150 |

| PLS7-415B4 | 1050 × 320 | 150 | 100 |

Related Video

FLB

One shot whole trimming with steel rule die cutting

-

Cutting machine with steel rule die which cuts whole cavities in a shot.

Connected with FLB forming machine, production line gets high speed and stable.

-

Dual-use for continuous trimming and cut sheet trimming. The sensor for feeding the sheet and the function of grip opening prevent from trimming slide.

| Model |

Max. Forming area(W × L, mm) |

Max. Forming Depth( mm ) |

Trimming force (kN) |

| PLB-3 | 800 × 600 | Height of formed part positive 100 negative 100 | 450 |

| PLB-2 | 600 × 600 | Height of formed part positive 100 negative 100 | 450 |

Related Video

FCS

Single station type vacuum Thermoforming Machine

-

Forming machine for thick gauge

-

Suits for pallet, bathtub, washstand and automobile components.

| Model |

Max. Forming area(W × L, mm) |

Max. Forming Depth( mm ) |

| FCS-660APA-W-L | 1050 × 2000 | 600 |

Related Video

Who is Asano?

Asano Laboratories Co. LTD is affiliated company of DJK Group.

Since it‘s foundation in 1953 ASANO has been designing, manufacturing and selling wide range of thermoforming machines. Such as Vacuum Forming, Vacuum Pressure Forming, Hot-plate Forming, Continuous Extrusion, Testing, Cutting & Punching.

Asano Laboratories Co., Ltd. has been manufacturing and selling over 5,000 thermoforming machines and post-treatment machines over 26 countries. Our machines for food container control 70% of the Japanese market share, and machines for refrigerator control approx. 100%.